Why the Old Ops Model Had to Go

Traditional infrastructure is slow and painfully outdated:

You’re chained to vendor timelines and useless support queues.

Replacement cycles never match real-world usage.

Stocking spare parts is basically burning money.

Even tiny datacenter fixes still require someone to physically do the thing.

That whole model is legacy and legacy just means liability.

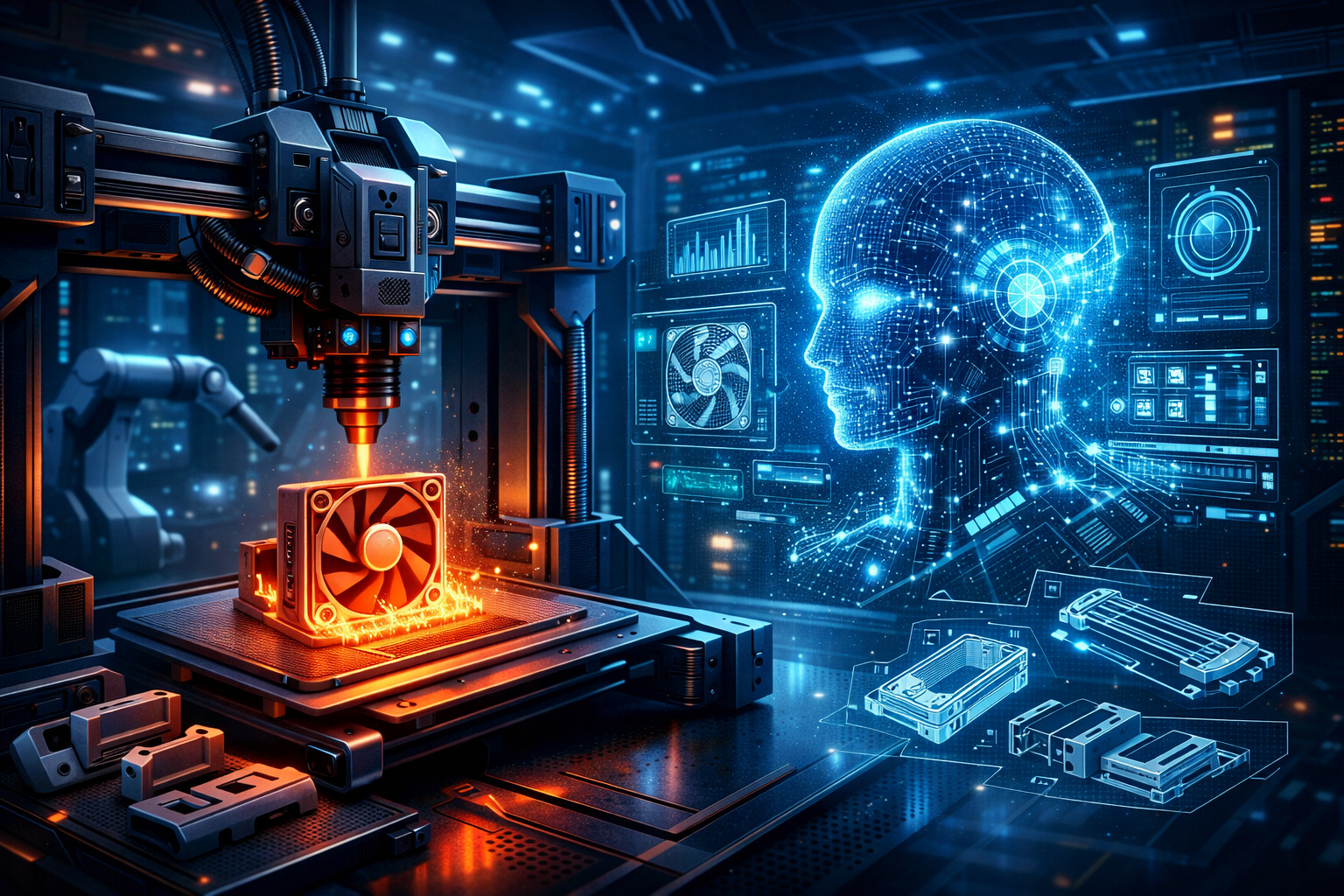

The New Workflow: AI + 3D Printing Running Ops Like a Pro

Here’s how the new pipeline works:

1. ML predicts hardware issues before they become issues

AI constantly watches thermal drift, vibration noise, PSU variance all the subtle signals humans usually miss. It flags parts long before Grafana even twitches.

2. Automated fabrication kicks in

As soon as the failure probability crosses the threshold, the printer gets to work. It churns out:

Fan brackets

Cable clips

SSD mounts

Airflow channels

Structural supports

Emergency covers

Zero procurement loops. Zero waiting.

3. The AI doesn’t just print, it optimizes

The model runs simulations like finite-element analysis and thermal/airflow modelling. Every printed part is better than the last. Your hardware literally upgrades itself over time.

4. Install is either robotic or human with AR assist

Depending on the datacenter setup:

A robot arm installs the part, or

A technician uses AR overlays that walk them through the exact steps

No confusion. No downtime.

The Actual Wins (a.k.a. Why This Matters)

70% drop in hardware-related downtime

MTTR cut almost in half

Parts cost basically zero

Low-risk incidents become fully autonomous

Scaling during traffic surges feels like flipping a switch

Best of all? No vendor lock-in. The entire pipeline is vertically owned.

The Bigger Picture: Self-Repairing Infrastructure

This system pushes us toward something wild: datacenters that heal themselves.

AI detects the failure

AI designs the fix

AI manufactures it

AI deploys it

Humans just keep an eye on things and sip coffee.

Server management stops being a never-ending firefight and turns into a horsepower multiplier for growth.